No, that’s not normal

Denver is a sanding circus, so we advise to choose wisely.

How to Spot an Amateur

How to Spot an Amateur

- Their floor sanders are rented

- They do not operate dust collection equipment

- They use finishing products that are lower cost and quality

- They lack a portfolio of previous projects

How to avoid a problem floor

Identifying a true professional just requires better questions

- Colorado does NOT require flooring professionals to undergo any testing or licensing requirements to operate a business. Therefore, the standards for quality and contractor accountability tend to vary a lot.

- Most contractors who are insured are covered for liability and accidents. Few insurers will cover a homeowner loss due to poor cosmetic quality in workmanship. If a contractor’s work is poor quality, then you may have to litigate to recover your losses.

Product Quality

Single Component

Finish that dries and cures without the addition of a chemical catalyst. This is a more budget friendly product.

Catalyzed 2 Component

These finishes use a chemical catalyst to cure the coating. Two component products have a higher cost, but offer better scuff and scratch resistance.

Floor Sanding

A refinishing project is the sum of all parts, which includes sanding skills, attention to detail, and application of professional products. Below is a list of flooring problems that can result from unprofessional workmanship.

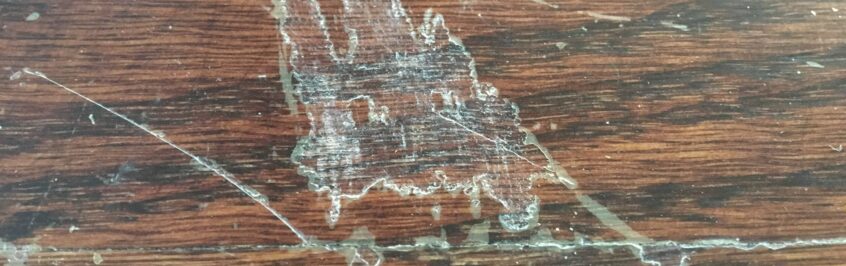

Soft Grain Wear-through

This floor is in the advanced stages of wear. The finish coating is missing in many areas. Due to the loss of a protective coating, the wood floor is seeing wear in the soft-grain of the boards. Eventually, if left un-treated the flooring will become water stained and is susceptible to mold growth. Floors with really rough sanding procedures and/or poor finish application can experience this type of wear over time. Frequent use of steam mops can also contribute to this condition.

Peeling Finish

Several factors will impact the long term durability of a floor. Peeling finish is essentially the kiss of death for a hardwood floor. In the picture above the top finish layer has lost its bond to the previous finish coat. There are many contributing factors to peeling, I have covered the process of peeling finish at length in a recent blog post. A contractor should use products and processes that are compatible with one another. Following manufacturer guidelines and using products from the same manufacturer can prevent this type of issue.

Dishout

This is the result of overly aggressive finish sanding that results in the ripple effect you see here. The less dense portion of the boards is called the spring-wood. This is not an acceptable result for floor finishing. Additionally, the floor will likely experience pre-mature wear because of the contoured topography of the floor. This phenomenon is so common around Colorado that it has the nickname “Denver dish out”.

Chatter

This is a picture of chatter in a floor. Chatter is a very subtle effect that sometimes is only able to be visualized, but does not have the same pronounced profile of wave. Chatter is often difficult to spot until later parts of the finishing process when the finish will highlight the problem. This defect is the result of poor machine maintenance in most cases. The issue is generally attributed to belt or drum machines and sandpaper tracking issues.

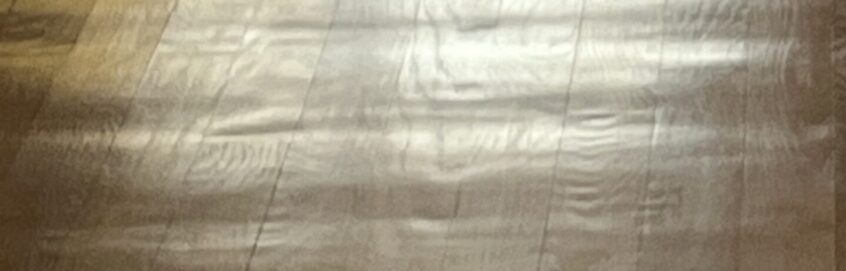

Wave

This is the result of changes in floor sanding pressure from a belt or drum machine during sanding. The picture above represents a floor we recently refinished. This was before we started the process. Not only was the defect visible, but you could also feel the undulation of the floor with your hand or foot. We fixed this floor with a few rounds of sanding and detailed the project on a blog post.

Sanding scratches

Sanding scratches are the remnants of the coarse sanding that show up during staining processes. They generally result from poor quality final finish sanding. Because of the steps and efforts to prevent sanding scratches, staining a wood floor will add to the price of an estimate. If you are having your floor refinished and stained darker, I would be careful hiring a contractor with the lowest price.

Great Expectations

Floor sanding is roughly a 3-5 step machining process to flatten a wood floor. It requires coarse sanding followed by finishing processes to remove any deep scratches. From there, are a few rounds of finish application and fine sanding. Skipping steps just doesn’t work for quality.

I would also encourage you to read our post regarding floor finish types. This will help you understand how to choose the finish type you prefer for your project.

Avoid the pitch

If you see these defects in your floor from sanding, then don’t accept excuses like “that will cure out with time”, “that just needs another coat of finish”, etc…Poor sanding cannot be hidden with floor finish.

Tools are expensive

Contractors who operate at the top level also require equipment to match. Buying and maintaining these tools costs money. Therefore, please don’t expect the highest quality from the lowest priced amateur.

Timelines

An average residential home can be refinished in 3-7 days. The factors that most impact a project would include existing wood stairs, color choice, and total square footage. How quickly you can move back in depends on finish cure times.

in writing

A quality estimate will include in writing some details regarding finish products and procedures by name. If an estimate includes only a price without details, you should be concerned or ask more questions about products.