Flooring Installation: Products and Process

Product Composition

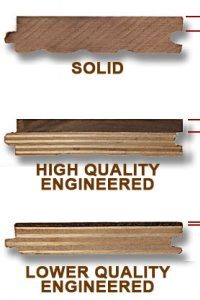

How a product is made will affect its long term performance and tolerance of RH swings during the seasons. Wood flooring in its broadest categorization is solid or engineered. From there, it is possible to factory apply a finish or apply a protective finish on site after installation.

Engineered flooring combines multiple layers of wood with adhesive to counteract dimensional change. The quality of materials and manufacturing used for engineered floors can vary widely in the flooring industry. Engineered flooring can serve a wider set of applications (in floor radiant heating, basements, etc…) than solid flooring in most cases.

Solid flooring is milled from timber through a series of processes. There are no adhesives or constructive processes required. The nature of how a solid floor is milled and kiln dried will impact performance during and after installation in some circumstances.

In all circumstances, these products still require owners to maintain relative humidity in a range compliant with installation and maintenance requirements.

Wear Layer

The Service Life of a Floor

Mechanical Fastener Types

Wood Floor Cleat

A single entry point fastener with barbs along the length. Wood flooring installation cleats offer good holding power. Due to one entry point versus two (like a staple), cleats are a better choice for dense or brittle wood flooring types.

WooD Floor Staple

Staples have two entry and holding points within the fastener. Staples offer exceptional holding power. Dense and brittle species of flooring may split during fastening with staples. Caution suggested.

Coverage Rate and Tools

Some flooring is held in place with adhesives. Using proper trowel and product type are essential to a quality installation.

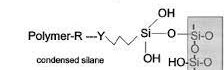

Silane vs Urethane

Silane adhesives are best for factory finished floors as they will not bond and affect the finished surface of products.

Moisture Barrier

Moisture barriers can be applied to the subfloor to mitigate flooring issues. Various forms of moisture barrier are available depending on the project specifications.

Glue Down Floors

There are situations in which flooring installation occurs with adhesive only. For example, an in-floor radiant heating system below a subfloor would be a situation where mechanical fasteners are NOT advised.

In wider plank flooring, as the distance between fastener rows increases, it may be necessary to glue assist the installation. The National Wood Flooring Association and many manufacturers advise the use of glue assist for 5″ or wider flooring.

“A b highlights other content on the page.

- DONT FORGET…

- Installation Instructions

- Product Coverage Rate

- Product Compatibility

Nailing Pattern

Flooring installation guidelines will specify the nailing intervals required for a wood floor to stay fastened to the subfloor below. The nailing pattern of a floor can be determined without destructive testing using magnets.

Board Width

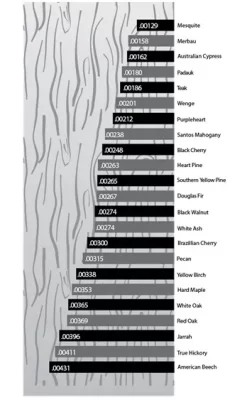

Board width can exacerbate the effects of moisture gain or loss on a wood floor. There is a formula that predicts average expansion or contraction of a solid wood floor.

Board width x % Moisture Change x (Species specific change coefficient)

For a 5″ wide red oak board that experiences a 2% MC change

5 x 0.0369 x 1% Moisture Loss = .01845″

The same example with a 2.25″ wide board

2.25 x 0.0369 x 1% Moisture Loss = .00830″

Acclimation

Acclimation is the process of allowing a flooring product to attain a moisture content compatible with the home prior to flooring installation. The length of this process can vary depending on flooring choice. The best strategy for acclimation is regular monitoring of moisture content within flooring until it is within an acceptable range determined by the manufacturer.

Prep

Achieving a good bond between flooring and/or mechanical fasteners requires a properly prepared subfloor. Contaminant free is essential for adhesives. Flat and well secured subfloors are essential as well.

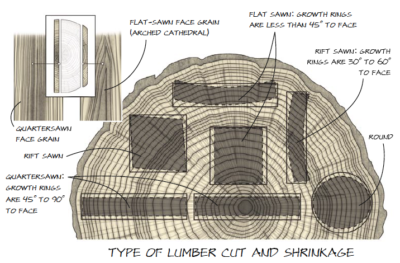

Grain Orientation

How flooring is sawn will impact its dimensional stability. As a general rule, expansion and contraction occurs tangentially. Boards are plain sawn, rift sawn, or quarter sawn depending on project requirements.

Inherent Stability

The ratio of tangential versus radial shrinkage a wood species undergoes is what determines the calculation for change coefficients. Species of wood flooring absorb and release moisture at differing rates.

The density of flooring and the distribution of trace minerals/sugars throughout wood fibers are determinants in these properties. If you are concerned about seasonal moisture changes, the impacts may be mitigated by choosing a wood flooring type that has better stability.