How Long Can you wait?

Water is not an innocent molecule when it comes to its ability to break down finish coatings on wood flooring. We recommend avoiding mops and water to clean your floors.

Finish Break Down

With enough time water can degrade the finish within the soft grain of a floor. In addition, peeling hardwood floors will start to degrade shown in the picture above.

Peeling hardwood floors

The kiss of death in most cases

The picture on the left was from peeling hardwood floor we had to refinish due to a contractor error.

An essential property of a flooring finish to consider is the elasticity of the coating. How coatings bond to a floor is called adhesion. The process of floor finishing is a multi step calculated art. It is essential that the layers of finish applied during a project adhere to one another and to the floor.

Contaminants during the preparation process can interfere with adhesion. The photo indicates the coating had a bond failure. The cause can be for a number of reasons.

Once a floor has started to peel intermittently, it is likely the process will not stop until the contaminated product is removed from the entire wood surface and re-applied properly. Sanding and finishing is required in most cases.

Finishing process equals value

Manufacturers specify a number of requirements for sanding procedures and how to apply their finish. The primary reason is that wood surfaces must be “burnished” properly to provide an even color and stilll allow adequate adhesion of a coating to that surface.

Burnish refers to the sanding procedures followed to achieve a a final texture on a wood surface. A wood surface that has been burnished too much, can result in a finish coating that may not penetrate and adhere. Surfaces that are burnished inconsistently can absorb stains or coatings differently.

The flatness of a surface can impact long term coatings performance. Flooring that has been sanded improperly can have dish-out within the soft grain. Following sanding, a floor with this issue can absorb finish in excess. If coatings are applied at an inadequate mil thickness during finishing, the soft grain of a floor can experience premature wear.

Whenever you consider the scope of a project in your conversations with your contractor, adhesion and finish performance are high value items. The type of finish applied and the sanding procedures varies greatly amongst most wood flooring contractors.

The biggest bait and switch used by bad contractors relates to the overall number of coats applied to a hardwood floor. If one contractor applies a coating at 600 square feet per gallon while the other applies at 400 square feet per gallon, then the end result will be vastly different. Depending on the type of finish, it is easy to vary coverage rates significantly by up to 50% per application.

The appropriate answer is to evaluate the TOTAL number of gallons used to finish a hardwood floor. Whether someone accomplished the finishing process in two or three coats becomes irrelevant. The type of finish applied and the applicator used also factor for durability and value.

Flat for the win

The flatness of the surface of a hardwood floor partially determines how well it will resist long term foot traffic. Oak is the predominant flooring type in most American homes and particularly plain sawn oak.

From the picture on the right you can see the way flooring is sawn impacts the appearance. Plain sawn oak flooring has more of what we call “spring wood” on the traffic surface. Spring wood is correlated with the accelerated growth of the tree during warmer months. The wood grain is less dense in these areas and absorbs finish and stain more readily.

During the sanding process, it is essential that proper finishing procedures are followed to minimize the density difference of oak. Overly aggressive sanding can result in a phenomenon known as “dish out”. The effect can leave an undulated appearance and inconsistent finish sheen across the floor.

Preparation

The perimeter of a hardwood floor and detailing will make or break appearance of a project. Wood species vary in density requiring different approaches in the finishing process.

Dishout

The result of aggressive and improper sanding. The issue is the result of inadequate flattening of the floor and improper finish sanding. The highly contoured surface can experience wear at an accelerated rate.

secure

Loose floors can be a contributor to finish adhesion issues. Prior to sanding and finishing a project they should be fixed. This can alleviate peeling and filler issues.

elasticity

Seasonal movement of flooring is a normal process. Wood floor finishes vary in how well they endure movement and bond to wood fibers. This performance specification should not be overlooked.

Finish categories

Essential to discuss is how protective coatings adhere to a hardwood floor. Coatings are connected to wood fibers via either: chemical bond, mechanical bond, or both. The chemical composition of a floor coating will determine how adhesion develops.

Essential to consider is that there are three factors that determine the longevity of a hardwood floor refinishing project:

- Sanding and finishing quality

- Products (When applied per manufacturer’s guidelines)

- Post project maintenance (cleaning, etc…)

Wood floors are protected via one of two general categories: film forming finishes or penetrating finishes. Each of these has a very different protocol for maintenance requirements, servicing, and repairs after the project is complete.

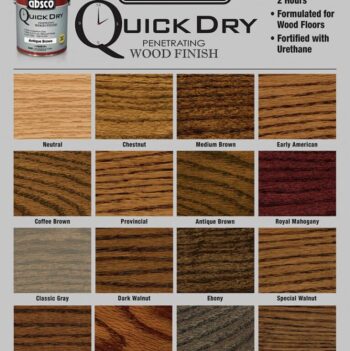

Penetrating Finish

This non film forming finish impregnates wood fibers and is burnished to a finish.

Waterborne finishes

Surface finish whose components are soluble in water and catalyzed various ways and rely on a mechanical bond for adhesion.

Conversion Varnish

Alcohol catalyzed chemically bonding surface finish. Excellent elasticity and adhesion.

Refinish or Repair?

Issue Solution

- Deep gouges

- Chipped finish

- Loose boards

- Peeling hardwood floors

- Replace boards or wax repair

- Refinish

- Secure PRIOR to sanding

- Sand the entire floor again

Waterborne Urethane

- Durable and easy to maintain

- Low odor

- Mechanical bond

- Lower elasticity due to coating hardness

Oil Modified Urethane

- Durable and easy to maintain

- Moderate Odor

- Cure times vary

- Mechanical bond

- Lower elasticity due to coating hardness

Penetrating Finishes

- Easy service and repair

- Handles seasonal movement well

- Annual maintenance suggested

- Fast cure/low odor

Conversion Varnish

- Excellent adhesion

- Requires adequate post finishing ventilation

- Readily repaired

- Durable reputation